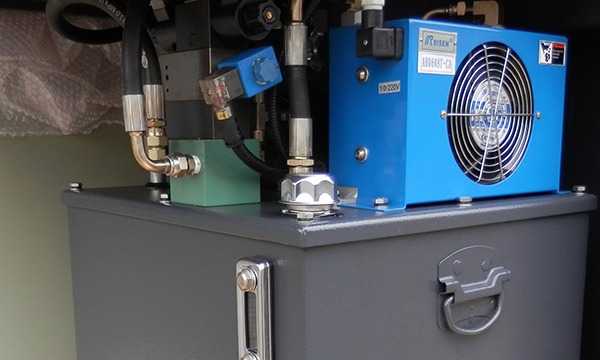

Hydraulic control

HORIZONTAL PIPE SHREDDER

APPLICATIONS:

- Pipe – Large Diameter Thick Walled Pipes, Corrugated Pipes etc.

- Bins & Containers – Wheelie Bins, Crates etc.

- Rolled Materials – Carpets, Artificial Grass, Industrial Reels etc.

EQUIPMENT INTRODUCTION

model: WTPH series

3E mechanical horizontal pipe shredding line mainly aims at the shredding, sorting and recycling of PE pipe、wire frame plastic composite pipes, and adopts two-stage shredding to obtain plastic.Plastic is effectively separated from the steel wire, and then the shredding line is equipped with a magnetic separator to completely separate steel wires from the plastic.

VIDEO

Plastic Pipe Shredding System

TECHNICAL FEATURES

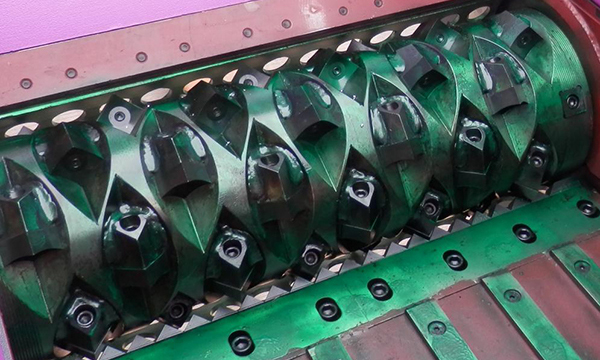

- Multi-rotor design - the number of rotors can be specified according to the material size

- High shear cutting between rotor and counter knives, suitable for thin wall pipe shredding

- Shock Absorbing Gearboxes reduces Stress on Drive Components

- Long Life Counter Knives can be adjusted to maintain cutter clearance

- Segmented loading chamber floor with Brass Guides

- High strength hydraulic cylinder with reinforced support frame, adjustable ram speed

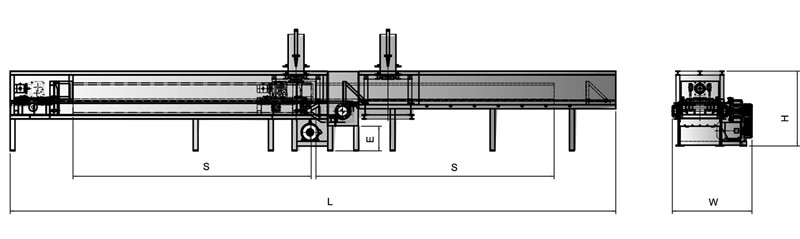

PARAMETERS

MODEL +

HORIZONTAL PIPE SHREDDER

|

Item Model |

WTPH4080 |

WTPH40100 |

WTPH40120 |

WTPH40150 |

|---|---|---|---|---|

|

Dimension L/W/H(mm) |

(3500+S)×1810×2600 |

(3500+S)×2160×2900 |

(3500+S)×2210×3300 |

(3500+S)×2700×3400 |

|

Height of discharge port E(mm) |

500 |

500 |

500 |

700 |

|

Cylinder Stroke (mm) |

400 |

600 |

700 |

1200 |

|

Rotor Diameter (mm) |

φ390.3 |

φ390.3 |

φ390.3 |

φ464.8 |

|

Main Shaft Speed (r/min) |

74 |

74 |

74 |

74 |

|

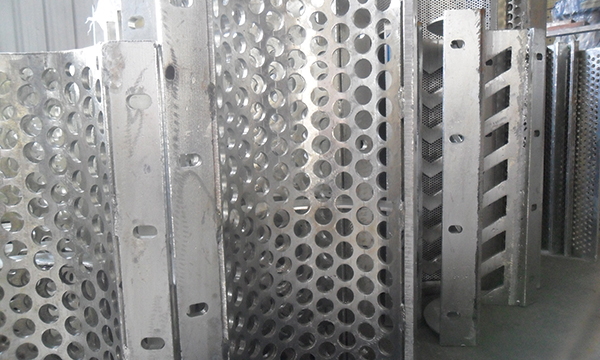

Screen Mesh (mm) |

φ40 |

φ40 |

φ40 |

φ40 |

|

Rotor-knives (pcs) |

42+4 |

54+4 |

66+4 |

90+4 |

|

Stator-knives (pcs) |

2 |

2 |

2 |

3 |

|

Main Motor Power (kw) |

37 |

45 |

37 |

90 |

|

The Cylinder Power (kw) |

3 |

3 |

3 |

4 |

|

Hydraulic Motor Power (kw) |

2.2 |

2.2 |

2.2 |

5.5 |