SOLUTIONS

PET BOTTLE RECYCLING LINE

3E Machinery provide a wide range of standard and bespoke plastic crushing and washing systems to meet the ever changing and demanding requirements of a modern recycling environment. The systems are capable of processing a wide range of plastic materials with varying levels of contamination including extremely heavy contamination such as PET bottles and milk bottles/ PE bottles.The whole production line is easy to operate, efficient and low energy consumption.

- SPECIFICATIONS

- MAIN EQUIPMENTSVIDEOS

- VIDEOS

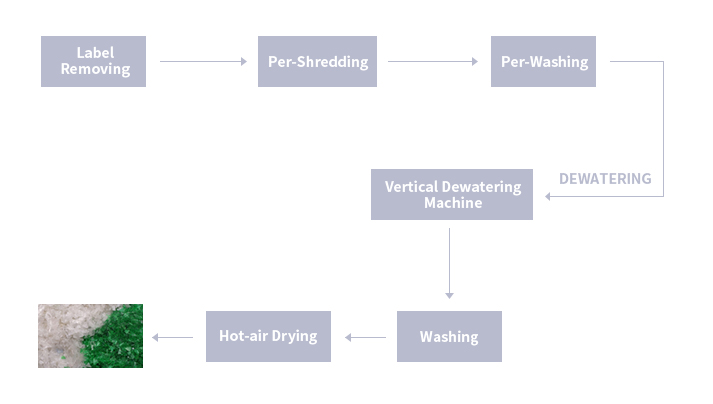

SYSTEM LAYOUT

EQUIPMENT CHARACTERISTIC

|

Capacity |

300-2000 kg/h |

|

Applications |

Suit for recycling Waste PET bottles, include Water bottles, Soft drinks bottles, Oil bottles,PE bottles/Milk bottles, PP bottles, etc. |

|

Specification |

The PET bottles Recycling Line is mainly composed of Single Shaft Shredder/Plastic Crusher, Helix Loader, Per-washer, Label Removing Machine, vertical Dewatering Machine, Dryer and other equipment.It is suitable for handling PET bottle. Material will be processed by label removing, crushing, washing, dewatering, and drying. The humidity of final output could be within 2%.The whole production line is easy to operate, efficient and low energy consumption. |

|

After-sales Service |

3E have a experienced installation team to provide professional installation guidance and training support. |

PET Bottle Grade

CASES

-

产量:2000 kg/h

投产时间:2015

HK.Milk Bottles Washing Line

-

产量:500kg/h

投产时间:2015

South Africa.PET Bottles Recycling Line

-

产量:300kg/h

投产时间:2012

Ecuador.PET Bottle Washing Line

-

产量:500kg/h

投产时间:2011

Dominica.PET Bottles Crushing Line

MAIN EQUIPMENTSVIDEOS

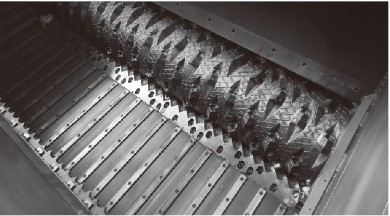

STEP-1 SIZE REDUCTION

Single Shaft Shredder

Plastic Granulator/Crusher

STEP-2 PREWASHING

|

Pre-WasherThis machine is mainly for cleaning PE/PP/PET plastic film and flakes that after crushing, to clean the dirty that mixed in the film. The exterior shell make by stainless steel, excellent in corrosion resistance, and the impeller by wear resistant material with dependable performance. Water injection device is awarded patent. |

|

TrommelTrommel is adopts for pre-treatment process to get rid of impurity including sand, metal and etc. It can reduce the abrasive wear of the following machine. |

STEP-3 WASHING

|

Rinse tankClean and separate impurities from materials according to their density. |

STEP-4 DEWATERING

|

Vertical Dewatering MachineThis machine is mainly used for plastic flacks which after washing. It can be mechanical dewatered and dried. The water contain of the output material is below 2.5%. The bearing is waterproof and it can work stably in a long time. The water contacting part is made of stainless steel304. |