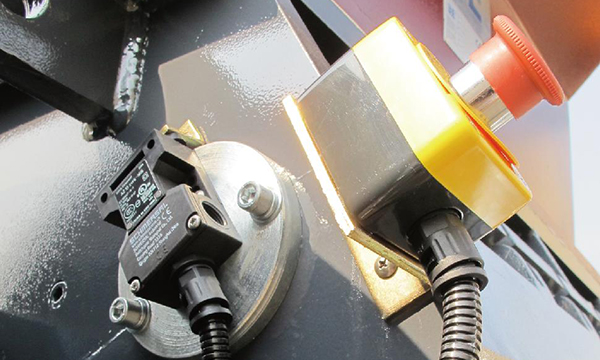

European CE certification

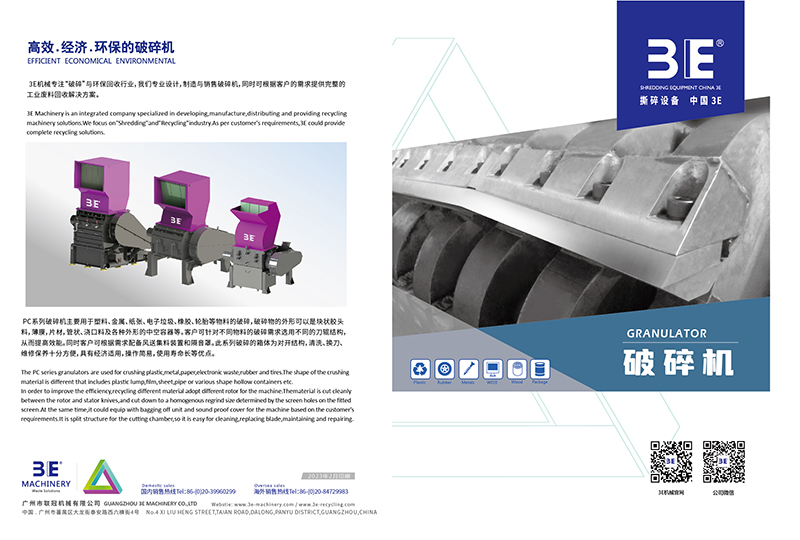

PLASTIC GRANULATOR

APPLICATIONS:

- Plastics - molding, profiles, films, etc.

- Rubber - tire, rubber, rubber products, etc.

- Paper and paperboard - confidential documents, production waste, packaging materials, etc.

- Copper cables - household, telecommunication and industrial cables, including s.w.a.

- Textiles - carpets (rolls and tiles), etc.

- Foam - production waste, etc.

EQUIPMENT INTRODUCTION

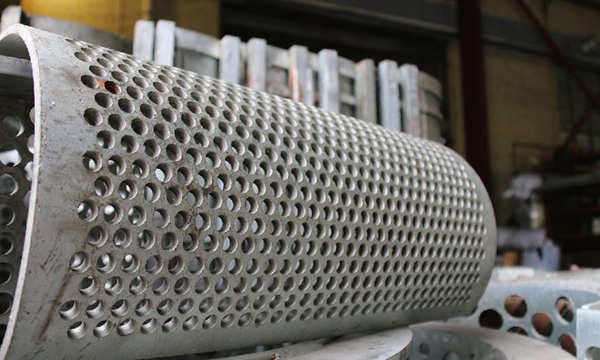

model: PC series

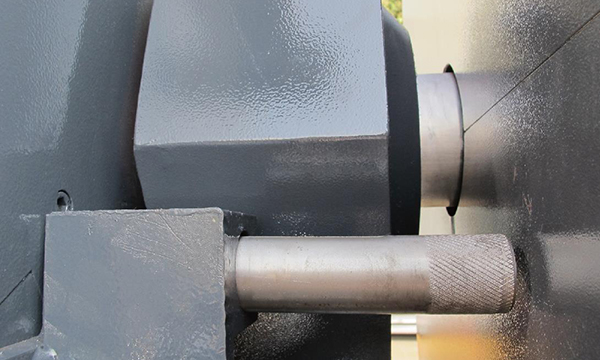

The PC series Granulators are heavy duty, high speed precision granulation machines designed for the rapid size reduction of various types of material in a single pass. The material is cut cleanly between the rotor and stator knives, and cut down to a homogenous regrind size determined by the screen holes on the fitted screen.

VIDEO

3E Product introduction

TECHNICAL FEATURES

- The suitable structure of cutter roller can be selected according to the broken materials required by customers

- High safety factor bearing, reduce the probability of bearing damage

- According to the demand, it can be equipped with pneumatic aggregate device and sound insulation structure device

- Independent control box, Siemens PLC system

- The whole system meets the CE safety standard

- It has the characteristics of economy, practicability, simple operation and long service life.

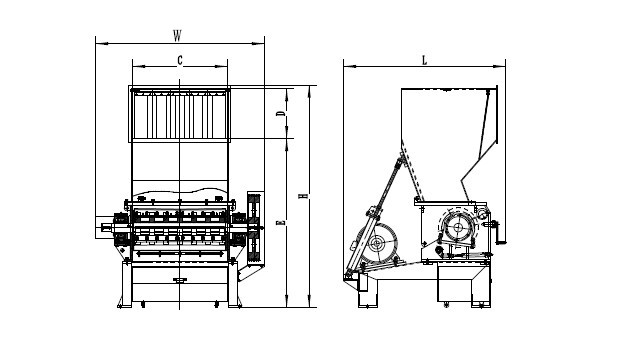

PARAMETERS

MODEL +

SMALL & MEDIUM PLASTIC CRUSHER/GRANULATOR

|

Item Model |

PC2660 |

PC3260 |

PC3280 |

PC4280 |

PC42100 |

PC42120 |

|---|---|---|---|---|---|---|

|

Dimension L/W/H (mm) |

1483×1328×1740 |

1486×1368×1711 |

1586×1568×1814 |

1770×1642×2425 |

1770×1842×2425 |

1760×2221×2530 |

|

Cutting Chamber C/D (mm) |

634×437 |

634×475 |

834×475 |

834×540 |

1034×540 |

1234×425 |

|

Height of discharge port E (mm) |

1567 |

1269 |

1369 |

1842 |

1842 |

1947 |

|

Rotor Diameter (mm) |

φ260 |

φ320 |

φ320 |

φ420 |

φ420 |

φ420 |

|

Main Shaft Speed (r/min) |

584 |

444 |

627 |

466 |

466 |

462 |

|

Screen Mesh (mm) |

φ8 |

φ12 |

φ12 |

φ12 |

φ12 |

φ12 |

|

Rotor-knives (pcs) |

3×2 |

3×2 |

3×2 |

3×2 |

3×2 |

3×2 |

|

Stator-knives (pcs) |

2×2 |

1×2 |

2×2 |

2×2 |

2×2 |

2×2 |

|

Main Motor Power (kw) |

15 |

15 |

22 |

37 |

45 |

55 |

|

Weight (kg) |

960 |

1470 |

1730 |

2800 |

3230 |

3650 |

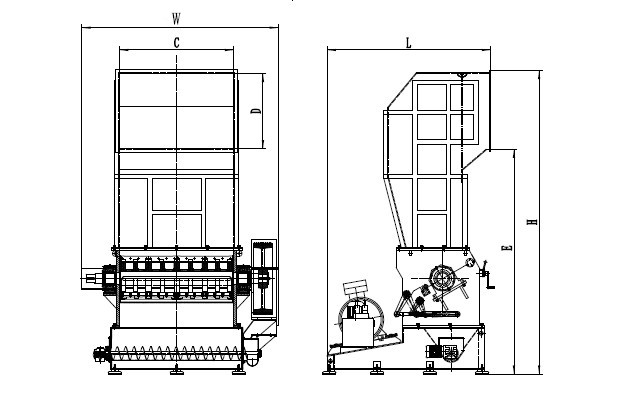

HEAVY-DUTY CRUSHER/GRANULATOR

|

Item Model |

PC52100 |

PC52120 |

PC66120 |

PC66160 |

PC80160 |

PC80200 |

PC80240 |

|---|---|---|---|---|---|---|---|

|

Dimension L/W/H (mm) |

2119×2025×2984 |

2070×2225×2984 |

2410×2320×4340 |

2335×2808×4337 |

3000×2900×4715 |

2735×3373×4564 |

2735×3580×4765 |

|

Cutting Chamber C/D (mm) |

1034×705 |

1234×705 |

1234×1080 |

1634×1080 |

1634×1000 |

2034×1000 |

2034×1000 |

|

Height of discharge port E (mm) |

2236 |

2236 |

3214 |

3214 |

3675 |

3514 |

3675 |

|

Rotor Diameter (mm) |

φ520 |

φ520 |

φ660 |

φ660 |

φ800 |

φ800 |

φ800 |

|

Main Shaft Speed (r/min) |

462 |

462 |

462 |

414 |

414 |

420 |

415 |

|

Screen Mesh (mm) |

φ12 |

φ12 |

φ12 |

φ12 |

φ12 |

φ12 |

φ12 |

|

Rotor-knives (pcs) |

5×2 |

5×2 |

5×2 |

5×2 |

5×2 |

5×2 |

5×2 |

|

Stator-knives (pcs) |

2×2/2×3 |

2×2/2×3 |

2×2/2×3 |

4×2/4×3 |

4×2/4×3 |

4×2/4×3 |

4×2/4×3 |

|

Main Motor Power (kw) |

55 |

75 |

90 |

132 |

160 |

200 |

250 |

|

Weight (kg) |

4200 |

5300 |

7650 |

9720 |

11400 |

13600 |

15780 |