SOLUTIONS

TIRE RECYCLING LINE

There is increasing pressure from the government, local councils and the public to reduce the levels of waste tire going to landfill or being exported. Significant recycling opportunities exist for investors to profit from the end products derived from tire recycling. There are more and more large volume applications for the rubber, steel and fibre derived from recycling tire which makes tire recycling an attractive opportunity for the recycling industry.

- SPECIFICATIONS

- MAIN EQUIPMENTSVIDEOS

- VIDEOS

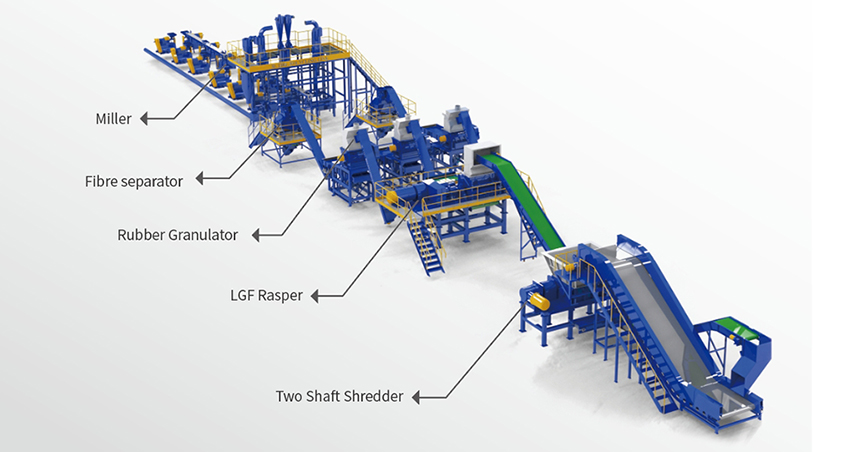

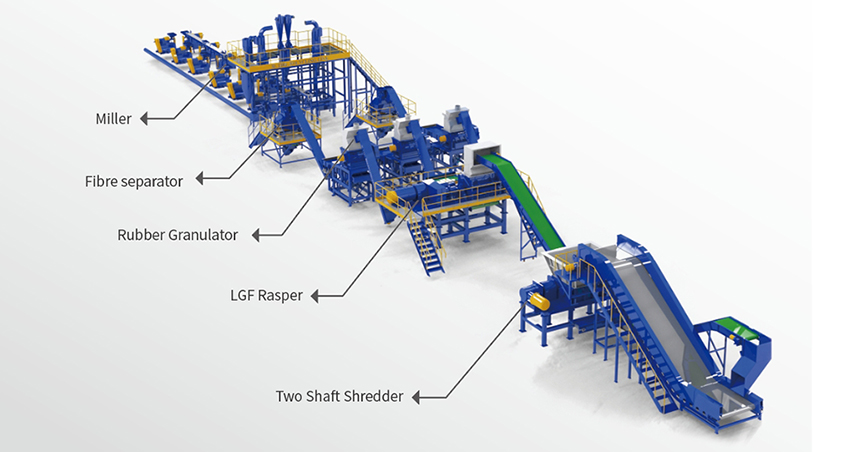

SYSTEM LAYOUT

The Rubber Crumbs, Steel and Fiber can be separated automatically

The rubber powder that recycled from the scrap tires are wildly used in the industries. It is mainly used as modified asphalt for high way construction and it is one of the biggest consumption markets for rubber granula.

TDF (50-60 mm)

Rubber Granule (1- 4 mm)

Steel wire

EQUIPMENT CHARACTERISTIC

| Capacity | 500-10000 kg/h |

| Scope of Application | Diameter of the tire : 400-3000mm , including car tire/ passage tire/truck tire/OTR tire. |

| Output Size | 5-100 mesh, Can be custom-made |

| Characteristic |

● Complete separation:The Rubber Crumbs、Steel and Fibre can be separated automatically. |

| Characteristic of blade |

● Long life cycle, High utilization, Multiple maintenance. |

| Equipment required area | About 400 square meter, 6 meter high |

| Patented | ZL 2010 2 0602082.4/ZL 2010 2 0602159.8 |

CASES

-

产量:6000kg/h

投产时间:2025

Tire recycling line in Algeria

-

产量:4000kg/h

投产时间:2024

Tire recycling line in Kazakhstan

-

产量:1000kg/h

投产时间:2000

Tire recycling line in Hungary

-

产量:8000kg/h

投产时间:2020

Tire recycling line in China

-

产量:8000kg/h

投产时间:2020

Tire recycling line in USA

-

产量:3000kg/h

投产时间:2018

Tire recycling line In India

-

产量:9000kg/h

投产时间:2016

Tire recycling line in Netherlands

-

产量:5000kg/h

投产时间:2015

Tire recycling line in Saudi Arabia

-

产量:3500kg/h

投产时间:2011

Belarus.Waste Tyre Recycling Line

-

产量:3000kg/h

投产时间:2015

USA.Tyre Recycling Plant

-

产量:5000kg/h

投产时间:2015

Saudi Arabia.Tire recycling Line

-

产量:3000kg/h

投产时间:2014

China.TDF Recycling Line

-

产量:3000kg/h

投产时间:2013年

Algeria.Waste Tire Recycling Line

-

产量:2500kg/h

投产时间:2012

China.Tire Recycling Line

-

产量:300kg/h

投产时间:2012

Russia.Old Tire recycling Equipment

-

产量:200kg/h

投产时间:2011

Honduras.Tyre Recycling Plant

-

产量:500kg/h

投产时间:2010

Indonesia.Tire Recycling Equipment

-

产量:1000kg/h

投产时间:2010

Brazil.Waste Tire Reycling Line

-

产量:4500kg/h

投产时间:2009

USA.Tire Recycling Machine

-

产量:4000kg/h

投产时间:2008

USA.Tire Recycling Line

|

Two Shaft ShredderCut the tire into rubber pieces (50 x100 mm) or bigger size rubber pieces which is easier for next step. |

|

LGF RasperCutting the pre shredded tire chips(size:50x100mm) into rubber crumbs (size:≤25mm). |

|

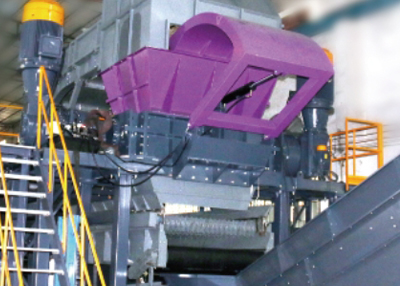

Rubber GranulatorThe rubber crusher is to crush the ≤25 mm rubber crumbs from the LGF separator into 0.5-4mm rubber particles. |

|

MillerRubber with particles 0.5-4mm is processed into 40-80 mesh. |