SOLUTIONS

PCB BOARD RECYCLING PRODUCTION LINE

Electronic waste is considered as urban mining. With the professional experience, Guangzhou 3E Machinery Company would like to provide our customers the environmental solution for recycling the PCB-board.

The PCB-board recycling line produced by 3E Machinery is mainly for PCB industry, the wasted board, frame, drilled powder from the PCB board production, and different electronic wasted collected from the environmental disposal company. And the recycling line is also to process waste circuit board environmentally. There are many features for this recycling line, such as easy maintenance and operation, reliable processing, high efficiency, energy conservation and environmental, ect.

- SPECIFICATIONS

- MAIN EQUIPMENTSVIDEOS

- VIDEOS

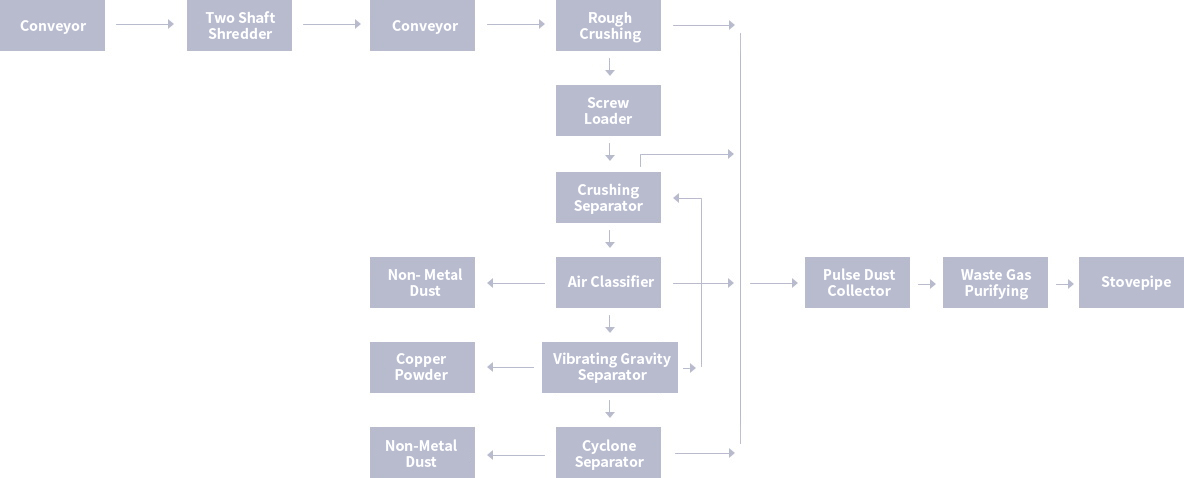

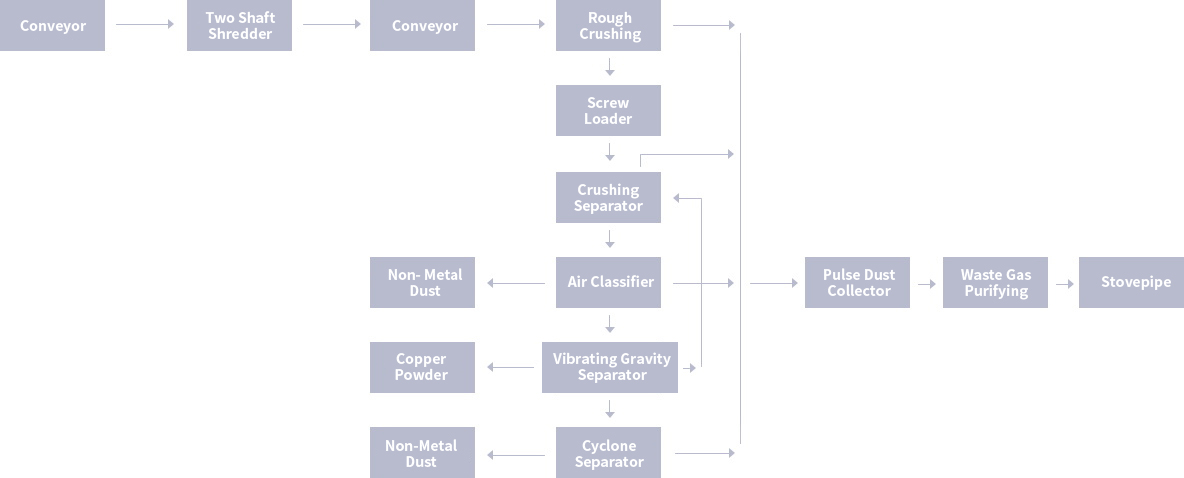

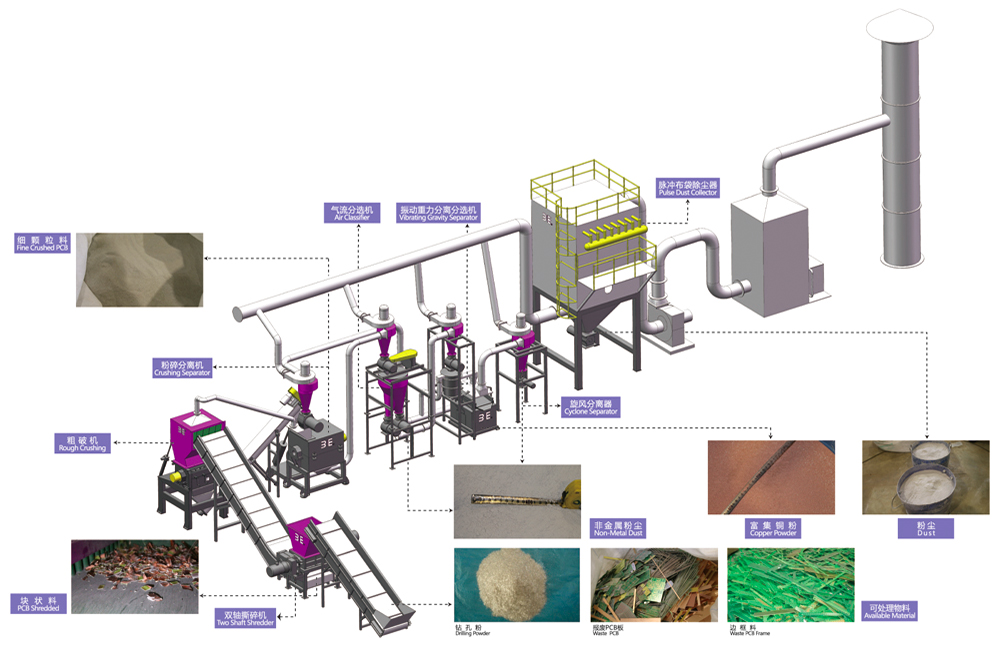

SYSTEM LAYOUT

Features

● Reasonable design, advanced technology, high automatic degree.● From the beginning to the end, the whole process is completely sealed. There is no pollution for the environment

● The capacity for processing PCB board: It is about 3000 tons annually. The recycling line could be designed as per the customer’s specific requirements.

● Energy conservation and environmental: The dust and exhaust from the production will be collected and processed before discharged. It could reach the Integrated Emission Standard of Air Pollutants (GB16927-1996). For the noise and vibration will be reduced and reach the Standard of noise at boundary of industrial enterprises (GB12348-90).

Proper Separation

Firstly the PCB boards are shredded into granulates, then the metal powder and nonmetal powder will be separated well by the classification and separation equipments. The powder and exhaust from the production will be processed by the pulse dust collector and exhaust purification equipment, when it reaches the environmental requirements then it will be discharged.

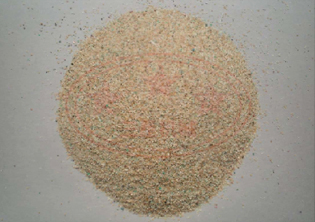

Output

● The metal recovery rate : 93%--98%

● The average metal content for the non-metal powder: ≤2%~5%

|

Two Shaft ShredderIt could shred the PCB board, wasted board, frame material and the other hard material into 20-50mm. There is no screen. |

|

Rough CrushingIt is mainly used to crush the materials from the two shaft shredder into the size within 10mm which is easier for the further crushing process. |

|

Crushing SeparatorIt is mainly to crush the boards into granulates then separate the metal and nonmetal from the PCB board eventually. |

|

Air ClassifierUsing different weight and centrifugal force of the material, it will take grade separation of the powder. Firstly the fine or light nonmetal powder will be separated. |

|

Vibrating Gravity SeparatorBecause the weight of granulate is different, using the centrifugal force principle, it could take the accurate separation for the metal powder and nonmetal powder. |

|

Cyclone SeparatorThere is rotated motion caused by the airflow tangential, in such case, the granulates with larger inertial centrifugal force will be throw to the wall of the hopper then drop down. The air will be discharged from the top outlet. This is a separation for the air and solid material. This separation equipment is used widely. |

|

Pulse Dust CollectorThe air with the dust get into the dust collector then it will follow from bottom to top. After being filtered by the bags, the dust will be stay outside of the filter bag. The dust will be drop down by the impact of the air flow and the air will be discharged through the bags. |