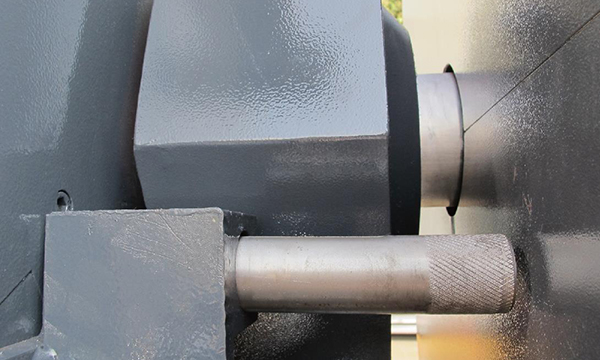

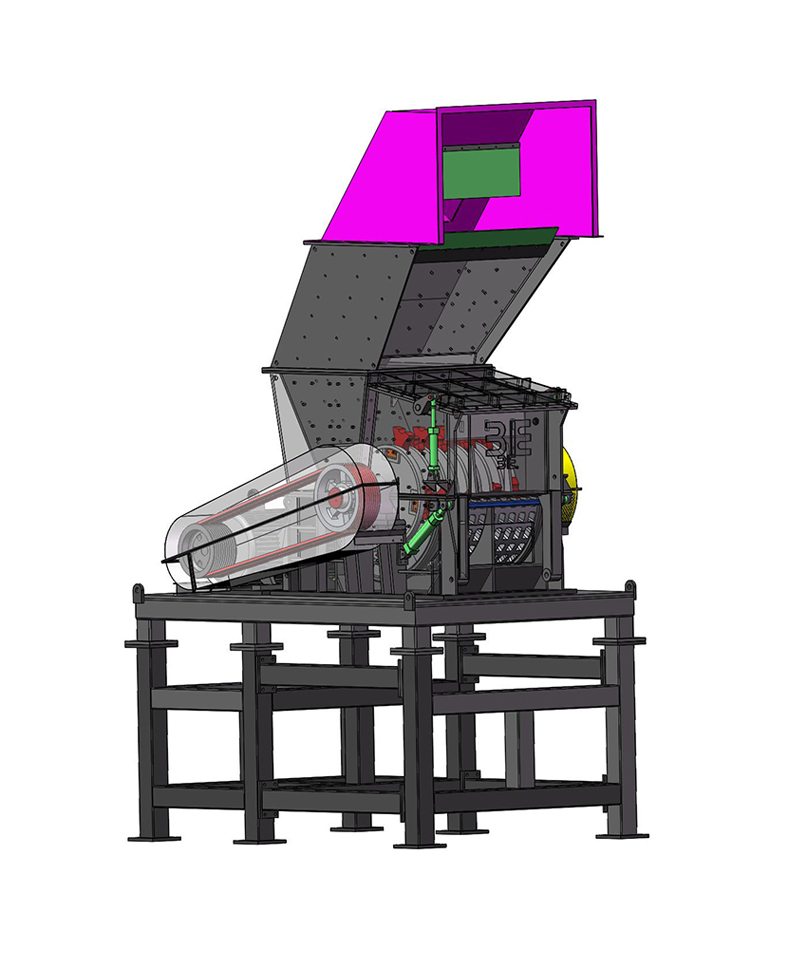

Rotor locking & external bearing

HAMMER MILL

APPLICATIONS:

- ELV’s (End of Life Vehicles) – Pre-shredded vehicle bodies

- Scrap Steel – Pre-shredded steel sheets, metal drums etc.

- Electronic Scrap – WEEE Directive Materials, meatballs.

- C&D Waste – Concrete, Timber, Plastics etc.

- Paper Industry Waste – Ragger tails

- Timber Waste – Pallet wood etc.

EQUIPMENT INTRODUCTION

model: ZP series

ZP series is welded by rigid steel structure, high manganese steel blade with high toughness and good impact duration. It is mainly suitable for the fragile material like electronic board, plasterboard etc.

VIDEO

3E Product introduction

TECHNICAL FEATURES

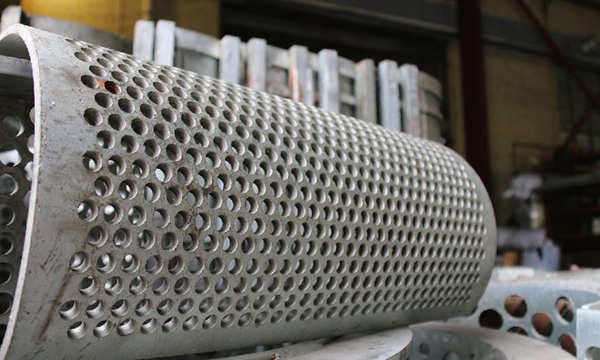

- The suitable structure of cutter roller can be selected according to the broken materials required by customers

- According to the demand, it can be equipped with pneumatic aggregate device and sound insulation structure device

- It has the characteristics of economy, practicability, simple operation and long service life

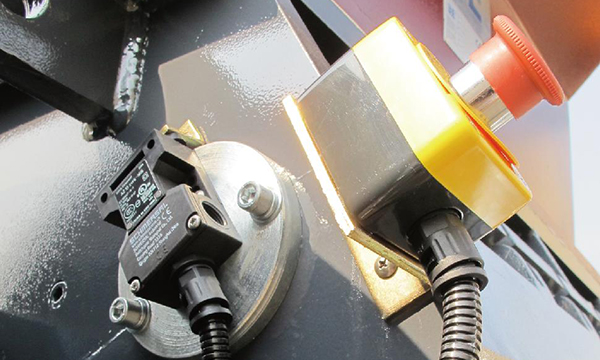

- The whole system meets the CE safety standard

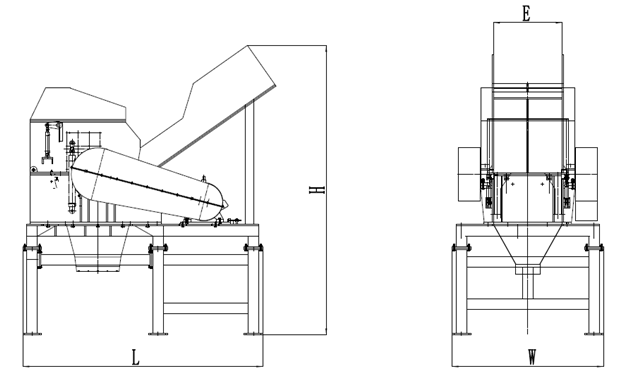

PARAMETERS

MODEL +

HAMMER MILL

|

Item Model |

ZP6045 |

ZP8060 |

ZP10080 |

ZP130120 |

ZP170160 |

|---|---|---|---|---|---|

|

Dimension L/W/H (mm) |

1750×1220×2210 |

2300×1650×2500 |

2850×2900×2760 |

4230×2290×5320 |

5340×6500×4800 |

|

Width of the input chamber E (mm) |

420 |

560 |

760 |

1160 |

1560 |

|

Rotor Diameter (mm) |

φ596 |

φ780 |

φ960 |

φ1260 |

φ1660 |

|

Main Motor Power (kw) |

37 |

55 |

90-132 |

160-250 |

315-400 |

|

Weight (kg) |

1500 |

3600 |

7800 |

21600 |

29500 |

|

Capacity (kg/h) |

500-1000 |

1000-1500 |

2000-3000 |

4000-6000 |

8000-12000 |