A nearly 10 pounds of waste lead-acid battery if discarded is the serious pollution of land and water, if the choice of physical recycling methods, will embark on a "rebirth" Tour --3E Machinery's new invention patents: LEAD-ACID BATTERIES RECYCLING LINE, full automatic closed loop production, through multi-channel after the process, waste lead-acid batteries will be isolated from the lead material, re made of lead. Regenerative lead production cost is 38% lower than the original lead; separation of waste plastics, re manufacturing battery shell and other plastic products; separating the waste acid to produce industrial products of sodium sulfate, and even can be combined into a new market of lead-acid battery.

3E Machinery's new invention patents: LEAD-ACID BATTERIES RECYCLING LINE

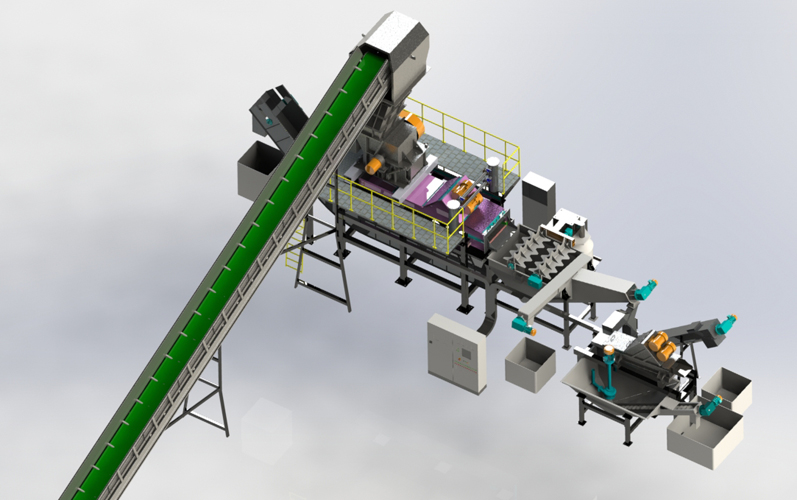

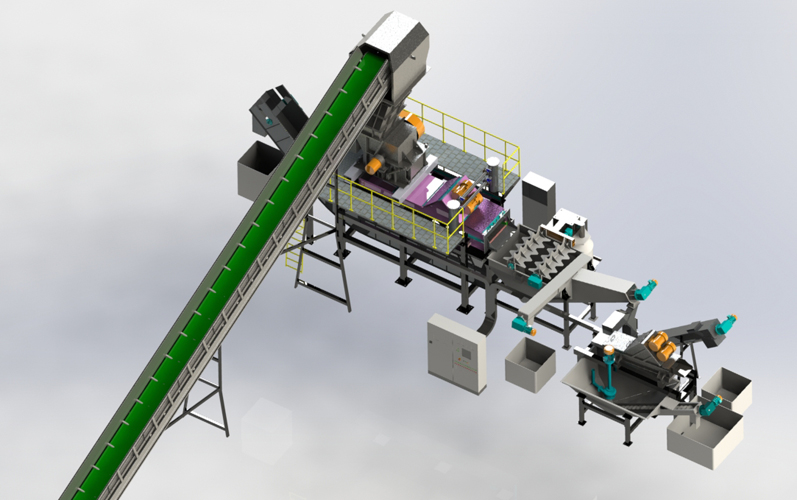

WORKING PROCESS

Our lead-acid battery recycling line includes the latest technologies which are developed completely by us, after a series of crushing and dissection, it will sort out diachylon, metal panel, heavy plastic, and so on. During the recycling process, in the first, the used lead-acid battery will be sliced by the cutting machine, then transport to crushing system through the conveying machine automatically. The shredded particles will come into the hydrodynamic collection system. Because of the different density of different materials, this system will sort out the diachylon, metal panel, heavy plastic, and so on. In the electrolyze solution of the batteries, the acid solution will be deprived out and come into the acid-solution processing system.

Capacity

60-80 pcs/hour

Characteristic

● The lead-acid battery recycling machine can start working without any treatment for used lead-acid batteries in advance

● The characteristic design including strip divided-screen is very convenient for maintenance.

● The size of the smashed particles is less than 80mm, the dissection efficiency is higher than 95%.

● PLC Auto-control

● All of the operations, can be finished automatically through our lead-acid battery recycling line, this avoid the direct harmfulness to operators’ health when they contact with those poisonous materials. The exhaust of noxious substance is also reduced greatly, so is the environmental pollutions.

Material

Output