{{withHeader.nameEn}}

{{withHeader.name}}

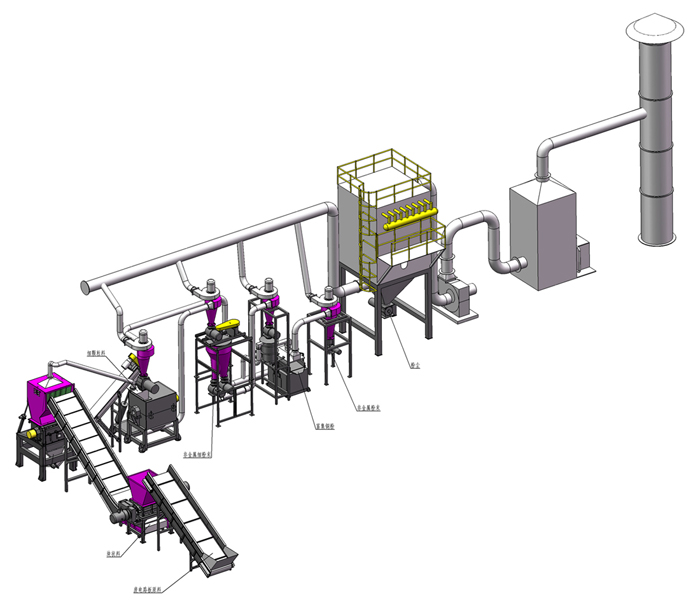

3E PCB Board Recycling Production Line

2017-02-17

Electronic waste is considered as urban mining. With the professional experience, Guangzhou 3E Machinery Company would like to provide our customers the environmental solution for recycling the PCB-board.

The PCB-board recycling line produced by 3E Machinery is mainly for PCB industry, the wasted board, frame, drilled powder from the PCB board production, and different electronic wasted collected from the environmental disposal company. And the recycling line is also to process waste circuit board environmentally. There are many features for this recycling line, such as easy maintenance and operation, reliable processing, high efficiency, energy conservation and environmental, ect.

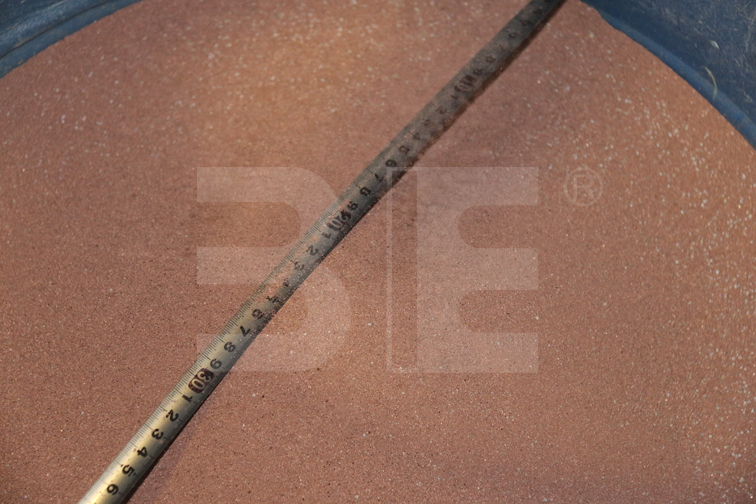

Copper Powder

Non-Metal Dust

Firstly the PCB boards are shredded into granulates, then the metal powder and nonmetal powder will be separated well by the classification and separation equipments. The powder and exhaust from the production will be processed by the pulse dust collector and exhaust purification equipment, when it reaches the environmental requirements then it will be discharged.

Features

● Reasonable design, advanced technology, highautomatic degree.

● From the beginning to the end, the wholeprocess is completely sealed. There is no pollution for the environment.

● The capacity for processing PCB board: It isabout 3000 tons annually. The recycling line could be designed as per

thecustomer’s specific requirements.

● Energy conservation andenvironmental: The dust and exhaust from the production will be collected andprocessed

before discharged. It could reach the Integrated Emission Standard ofAir Pollutants (GB16927-1996).

For the noise and vibration will be reduced andreach the Standard of noise at boundary of industrial enterprises

(GB12348-90).