{{withHeader.nameEn}}

{{withHeader.name}}

3E Standpoint--New production equipment and new process for crushing waste tire into 30 mesh rubber powder

2017-08-28

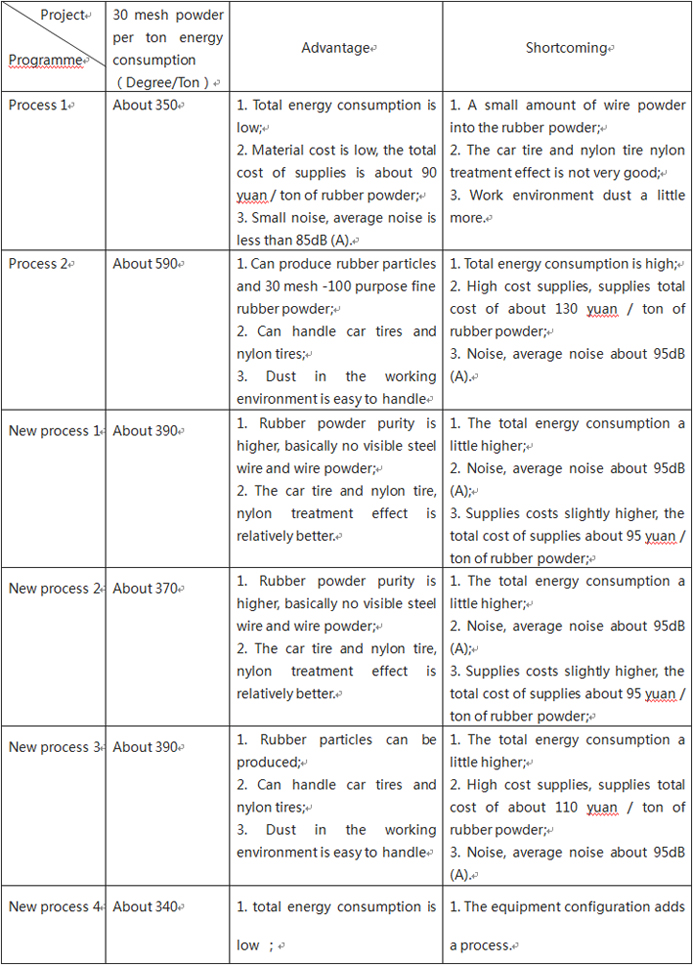

As for the broken tires and the 30 mesh powder (national standard 30 mesh) equipments, we usually have the following kinds:

Process 1: Two shaft shredder (discharging 50X50mm glue block) + groove light roller breaking machine;

Process 2: Two shaft shredder (discharge 50X50mm glue block) + LGF Rasper (or middle crusher) (discharge 15mm particle) + Rubber Granulator (or called fine crushing machine) (discharge less than 4mm particle) + Miller.

According to the requirements of 3E mechanical feedback and years of design experience with domestic and foreign customers, design the following four kinds of new equipment and new technology, these four kinds of process has landed in the use of multiple customers, with the common process of domestic comparison, each has advantages and disadvantages, to share with you now and discuss.

New Process 1: Two shaft shredder (material 50X50mm glue block) + LGF Rasper (or middle crusher) (discharge 15mm micelle) + Groove light roller breaking machine;

New Process 2: Two shaft shredder (discharge 50X50mm rubber) + LGF Rasper (or crushing machine) (material 15mm particles) + Double roller breaking machine;

New Process 3: Two shaft shredder (discharge 50X50mm rubber) + LGF Rasper (or crushing machine) (material 15mm particles) + Rubber Granulator (or crushing machine) (material less than 4mm particles) + Double roller breaking machine;

New Process 4: Two shaft shredder (discharge 50X50mm rubber) + channel light roller breaking glue machine (discharging particles less than 2mm) and gel breaking machine + Double roller breaking machine.

(since the process 1 is the process used by most of the customers in China at present, the comparison of the following advantages and disadvantages is mainly for the process 1).

Analysis:

3E machinery through the years meet the demand of different customers customized design of these schemes, with the commonly used technology of 1, only four of new technology in energy consumption is slightly lower, and other new technology in energy consumption and supplies, will be 1 higher than the process, but if customers face not only to get the rubber particles and rubber powder and rubber powder over 40 mesh, or customer handling car tires and nylon tire, the other process also has its advantages, so we need to configure the equipment according to the actual situation of customers.

Use case of new process 1

Use case of new process 2, new process 3, new process 4