{{withHeader.nameEn}}

{{withHeader.name}}

The purity of copper up to 98%-3E waste PCB physical environmental recycling method

2017-06-21

Craftsmanship-As a key point of new era manufacturing be written into the<government work report>by the prime minister. “Concentration, persistence, study, accurate and meticulous…” Not only is The spirit of craftsmanship, but also is standard of 3E MACHINERY. Our waste PCB recycling production line not only e strict with each production link and working procedure, but also carefully thought about every detail. Craftsmanship throughout the whole process, Expect customers to fully realize the value of the product.

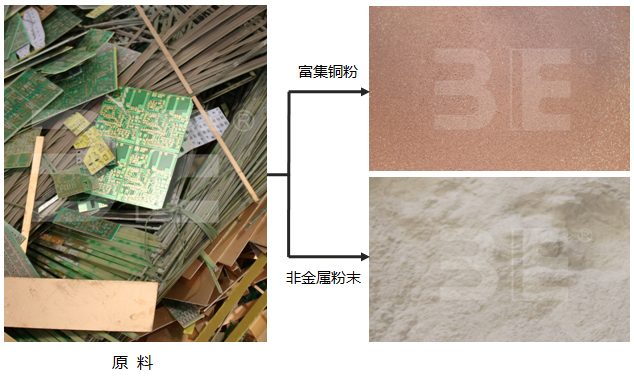

Electronic waste is known as “urban mines”, It is an important renewable resources of nonferrous metals. Waste PCB mainly composed of metal and nonmetal materials, Metal materials has greater toughness, and nonmetal materials with higher brittleness. Due to large differences between toughness and brittleness, and in general when crushed to less than 10mm, Metals are separated up to 98%. Nonmetallic powder can be applied to wood plastic, section bar, composite board and fireproof products field.

In waste PCB recycling production field, Currently wet processing, pyrogenic processing and physical mechanical processing are mostly used. 3E MACHINERY’s technology is physical mechanical processing and it also commonly used in Europe and America.

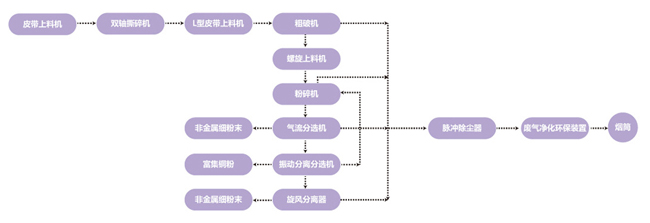

3E MACHINERY waste PCB recycling production technical process: Shredding→Rough Crushing→Crushing Separation→Air Classification→Vibration Separation→Environmental protection processing.

Process flow diagram

1.Shredding technics: Waste PCB material send into the twin shaft shredder by conveyor, the large size of waste PCB is processed into bar and block materials about 20mm wide. To meet the processing requirements of the next step;

2. Rough Crushing technics: The bar and block materials was sent to rough crushing equipment are further processed into granular materials with diameter ≤10mm, and evenly send to crushing separator into next step processing;

3. Crushing Separation technics: It is further crushed granular materials, in order to achieve separation of metal and nonmetal, to meet the processing requirements of the next step;

4. Air Classification technics: It is used by different specific gravity of materials and air rotation centrifugal separation, to preliminary classification and separation. It could be separate the fine and proportion light nonmetallic material, and make the proportion metal and nonmetal mixture of homogenization and concentration. Ready for the next selection process.

5. Vibration separation technics: It is selection process, the larger particles mixture of metal and nonmetal get from the primary selection, and It will be further classification and separation. It is used by a certain frequency reciprocating vibration of the screen and wind action of blowing and suction. To constant separating metal powder. The vibration frequency and air volume are adjustable, so purity of the metal powder could be set according to customer requirements, And the maximum purification rate for 98%.

6. Environmental processing: Due to the production line is mainly composed of crushing, classification and separation equipments, so it will be make A lot of dust and exhaust gas during the production run. In order to prevent the pollution of the production site and the surrounding environment. The production line basically using negative pressure of sealing pipeline transportation method. Through the effective combination of cyclone Separator, pulse dust collector and fan, Dust and exhaust gas was orderly collection and dust removal, air purification processing.

Output

Metal recovery rate: 93%~98%;

The average metal content of nonmetal powder: ≤2%~5%.