{{withHeader.nameEn}}

{{withHeader.name}}

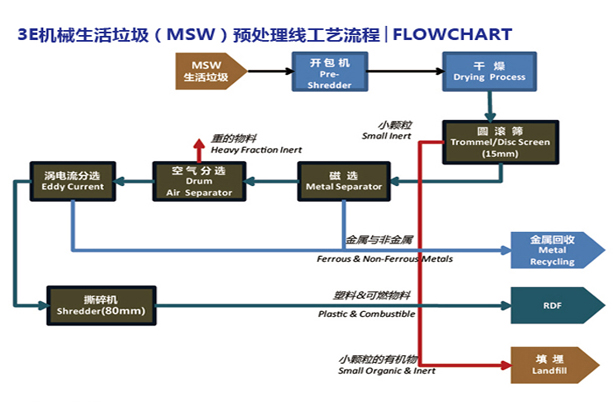

3E Municipal Solid Waste Shredding System

2017-08-28

RDF (Refuse Derived Fuel refuse derived fuel), pretreatment and processing effectively is garbage, and then as a solid fuel to be recycled, and provides a new idea for waste energy, and RDF derived fuel technology has become a new force in the field of waste utilization, will be a growth point of the new energy industry.

3E Municipal solid waste shredding system, can effectively separate RDF derived fuels from msw. High quality RDF fuel is characterized by uniform size and uniform calorific value. The molding process can increase the calorific value of waste by about 4 times, and it is easy to transport and reserve. RDF derived fuels can be used for energy recovery in power plants, and energy can be efficiently utilized in the form of electricity. Burning ash can be used as an effective component in making cement and broaden the road for the energy of garbage.

According to the material: After separation of garbage screening, in plastic bags, cardboard, packaging, wood, waste plastics, waste paper, wood, PVC and other combustible waste, containing a small amount of glass, small gravel and other debris.

Processing capacity: More than 1.5-5 tons / hour.

Discharging size: Less than 80mm, the size of the guarantee rate of more than 90%.

Moisture content: Less than 10%.

Process: To use the mechanical method of garbage classification, according to the different material properties, it can be recycled parts separated by magnetic separation process, wind separation and non metal screening steps, including screening, crushing, drying, molding, no harm and the formation of granular fuel.

Materiel

Output